Especially with carbide saw blades, the operator must pay special attention to the load weight on the carousel of the coating machine. This weight can easily reach more than 1 ton total weight. If the weight exceeds the maximum allowable load, it can have a negative effect on the rotation during the coating process, resulting in poor distribution of the coating in the chamber or even damage to the carousel, e.g., the rotary drive.

On the other hand, saw blades react to large temperature differences and can rapidly lose cutting force or become deformed. Due to the high content of heat-sensitive steel in these tools, precise control of the process temperature is essential.

PVD coating therefore requires units that can optimally handle the masses of the saw blades and whose heating and cooling times are adapted to temperature-sensitive materials.

The custom coating solution for PVD coating of saw blades

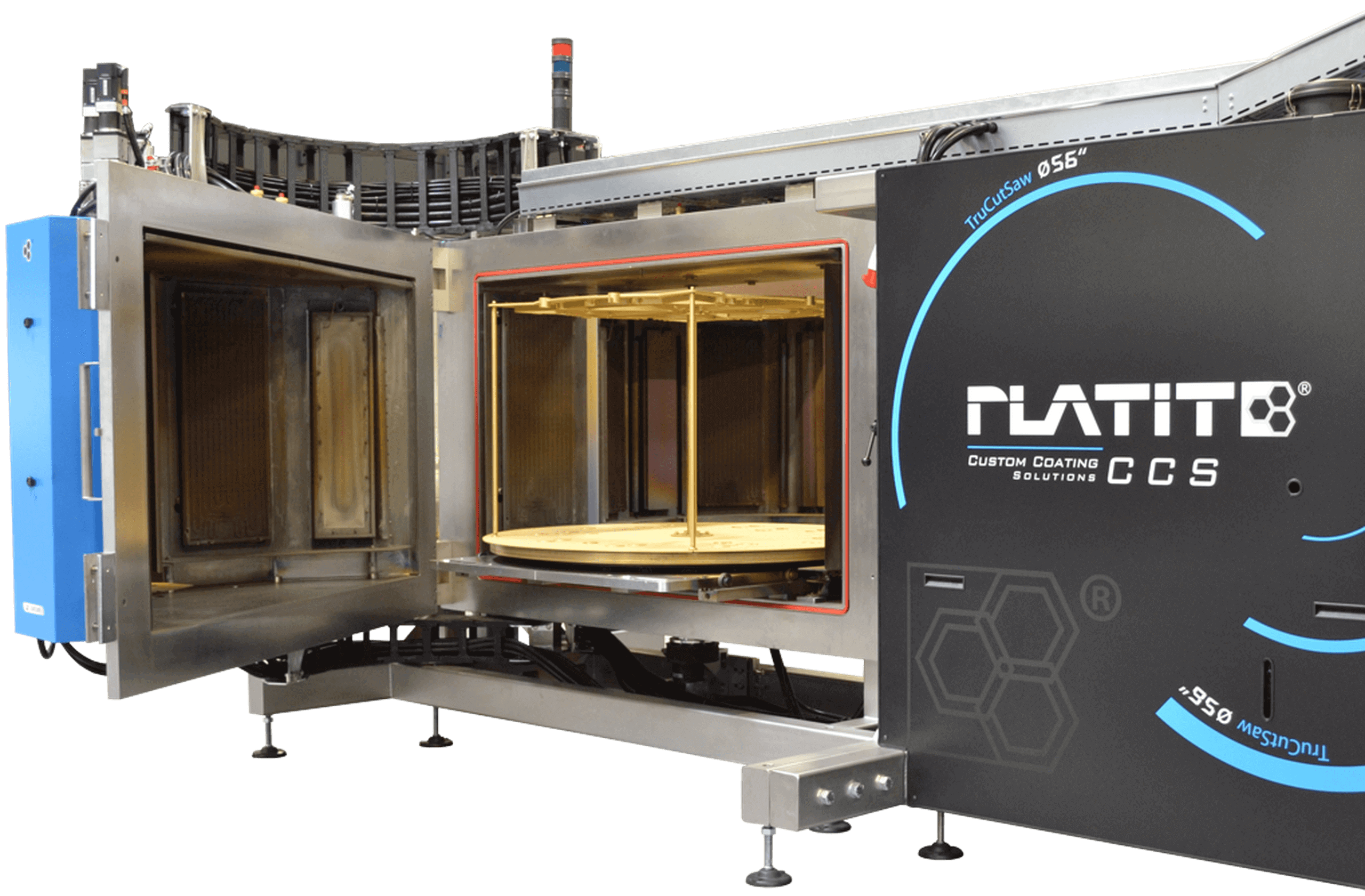

For high-quality, durable tool coating, PLATIT has designed and developed custom coating solutions specifically for saw blades.

- The dimensions of the coating chamber are suitable for extra-large tools and substrates. Specially designed saw blade attachments prevent saw blades from moving during the coating process due to thermal expansion and centrifugal forces.

- The modular carousel design allows maximum flexibility in loading, so that even different saw blade radii can be changed without problems.

- The temperature control is specially developed for the coating of saw blades. The unit keeps the temperature within a very narrow range. The chamber is heated in stages to about 300°C. The chamber can only be opened when it has cooled down to less than 100°C.

- In addition, etching parameters are adjusted to prevent damage to the cutting-edges of the circular saw blades.

Example:

PLATIT PL2011 coating unit for Tru-Cut Saw

Tru-Cut Saw is a well-known manufacturer of saw blades in the U.S. The Brunswick, Ohio-based company manufactures saw blades of various dimensions and for all types of applications, from wood to metalworking. The largest saw blades ever made were over 3000mm in diameter at Tru-Cut.

Comparison PL1011 G4 vs. PL2011

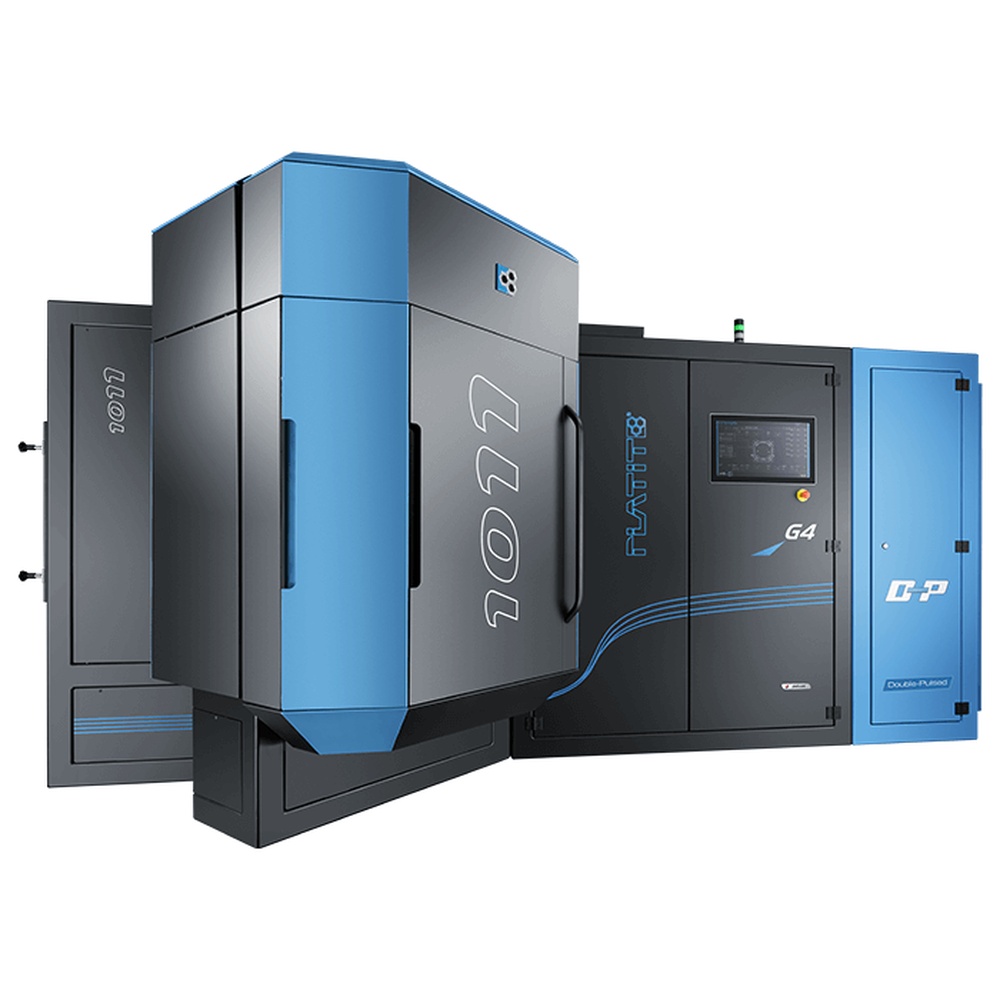

PL1011 G4

PL2011

Max. coating volume [mm]

ø715 x H805

ø1400 x H700

Max. load [kg]

750

1800

Arc technology

4 x Planar cathode, upgradable for Double-Pulsed feature

6 x Planar arc cathode, 4 of which pulsed with ARC power supplies

DLC

DLC1

-

Nitriding

Yes, upgradable

-