The video, starting at minute 17:33, explains the process in more detail.

LGD® etching process for PVD coating

LGD® stands for Lateral Glow Discharge, the patented etching process in our PVD coating units.

In addition to cutting-edges (e.g., of rolling cutters, punches and dies), complicated surfaces and cavities can also be reached using LGD®, as the flow of electrons between two cathodes creates a plasma with a high ion density in the rotating unit.

LGD® has these advantages in particular:

- Low “antenna effect” due to low bias voltage

- Increased mean scattering distance

- Better etching penetration, which leads to improved etching of the grooves

Use of a shutter

A shutter covers targets to isolate them from the plasma in the chamber. This allows the targets to be treated separately:

- The targets are cleaned by igniting an arc behind the shutter on the target surface without contaminating the tools.

- The shutter is only opened after the target has been cleaned, which provides ideal conditions for optimal coating adhesion and pure, non-contaminated target material can be used for the coating.

The 3D etch indicator

- Provides a 3D profile of the plasma etching effect

- Prevents etching that is both too weak or too strong

- Improves the performance of coatings in targeted applications

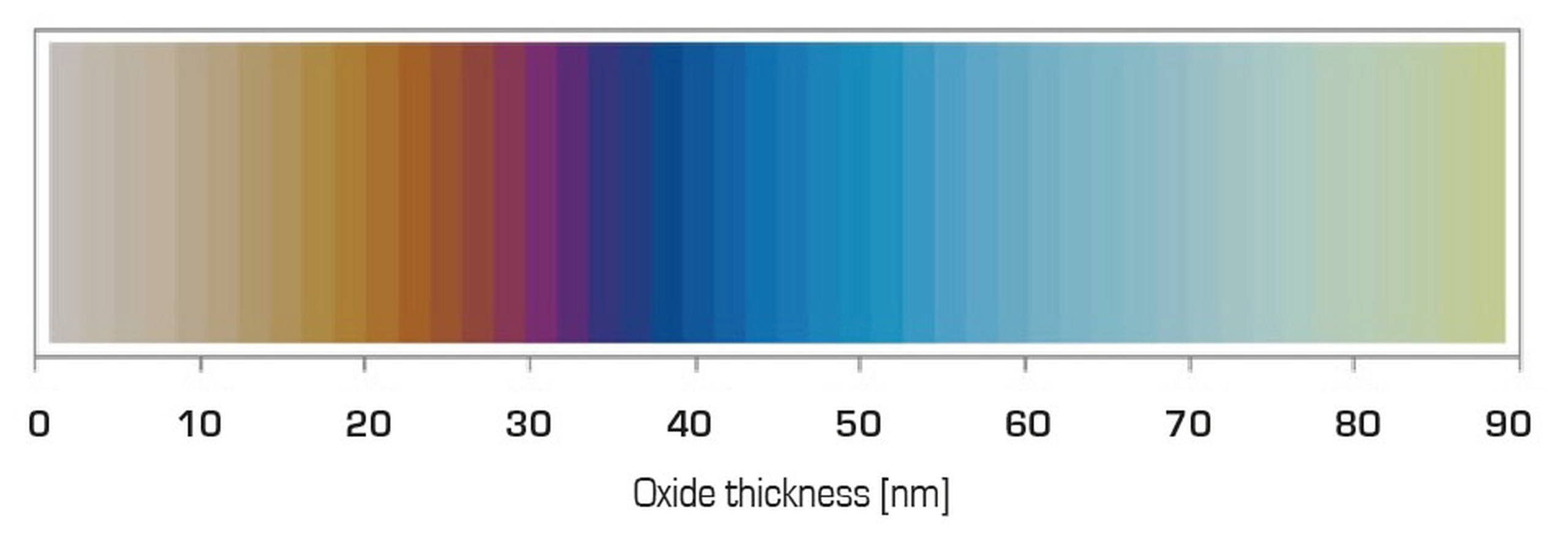

Interference color scale from [1] Antończak, A. J., et al. (2014). The influence of process parameters on the laser-induced coloring of titanium. Applied Physics A, 115(3),1003 – 1013

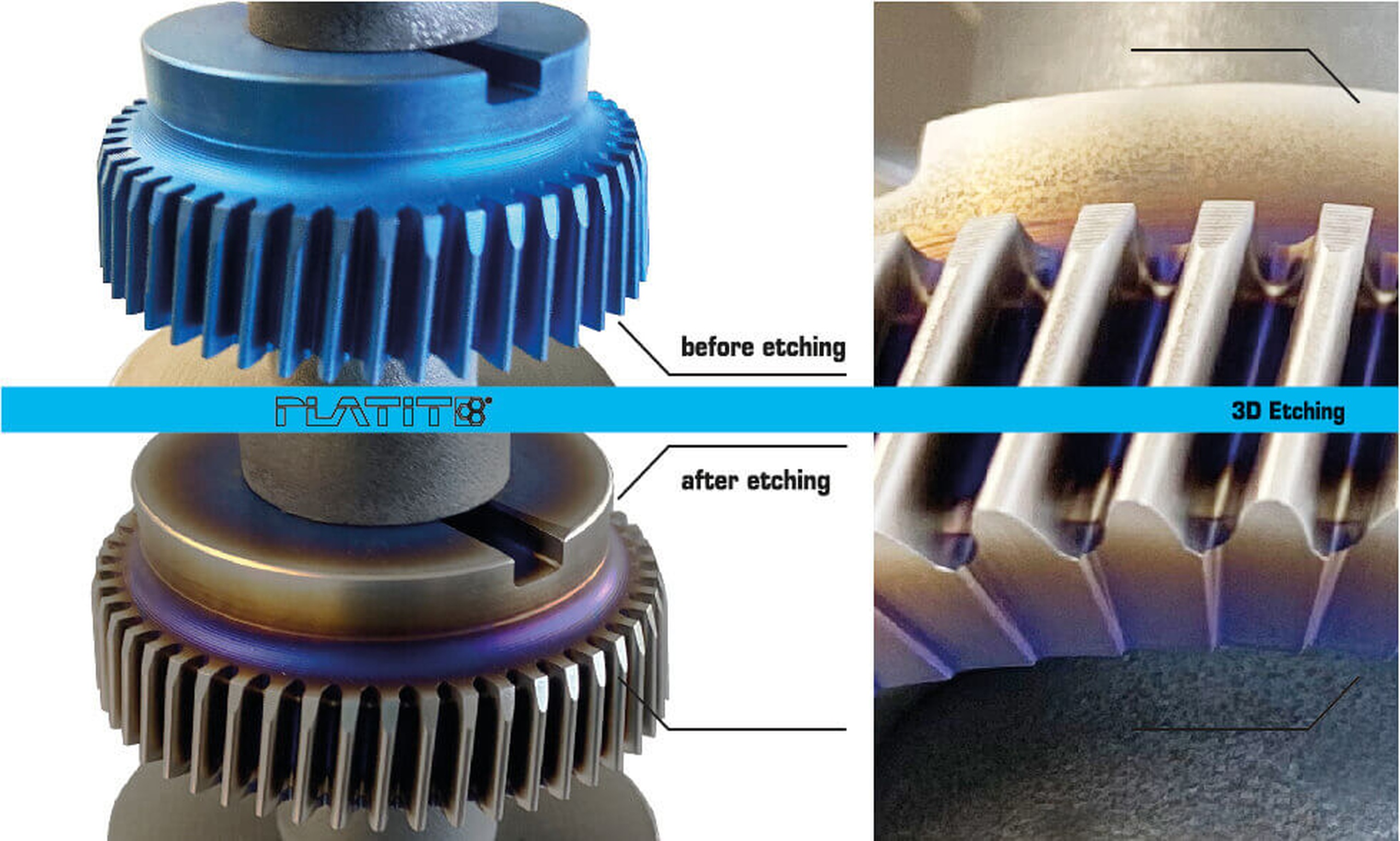

In order to generate a 3D etching profile, the samples are first coated with layers that reflect only a single interference color (e.g., blue) evenly. Subsequently, these samples are subjected to a plasma etching process with a defined time period.

Since the interference color of a coating is directly related to its thickness, the resulting color at any point on the surface can be used to determine the etching effect at that particular location with a high resolution (±5nm). PLATIT's 3D etch indicator thus enables the selection of the right combination of etching parameters and ensures that the selected etching strategy results in optimal material removal from the surface.

While usually only 1D or 2D measurements of plasma etching are possible and optimization requires a separate tool test for each individual parameter set, with the help of the 3D etch indicator, the etching effect is already visible to the naked eye immediately after the plasma etch test.

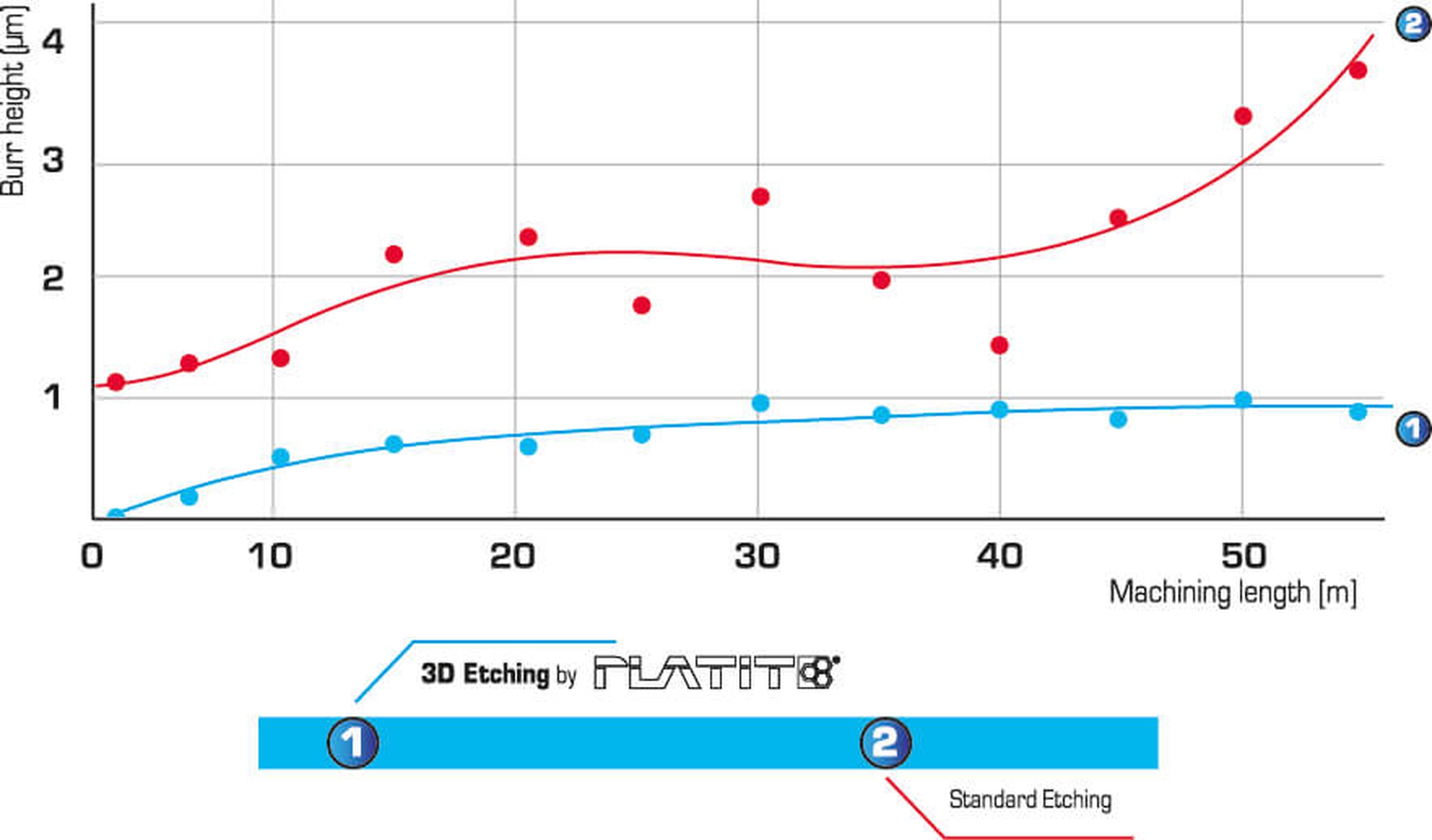

The diagram shows the result of targeted optimization of plasma etching on microtools. Compared to the commonly used standard etching, a much lower degree of burr height was observed in the case of 3D etching.

Would you like to learn more?

Further information can also be found here (please click to open):

- "PLATIT's 3D etch indicator"

- or if you contact us.