PLATIT PL1011 G4 – for maximum productivity

Coating systems overview

PLATIT S-MPuls – for coin minting

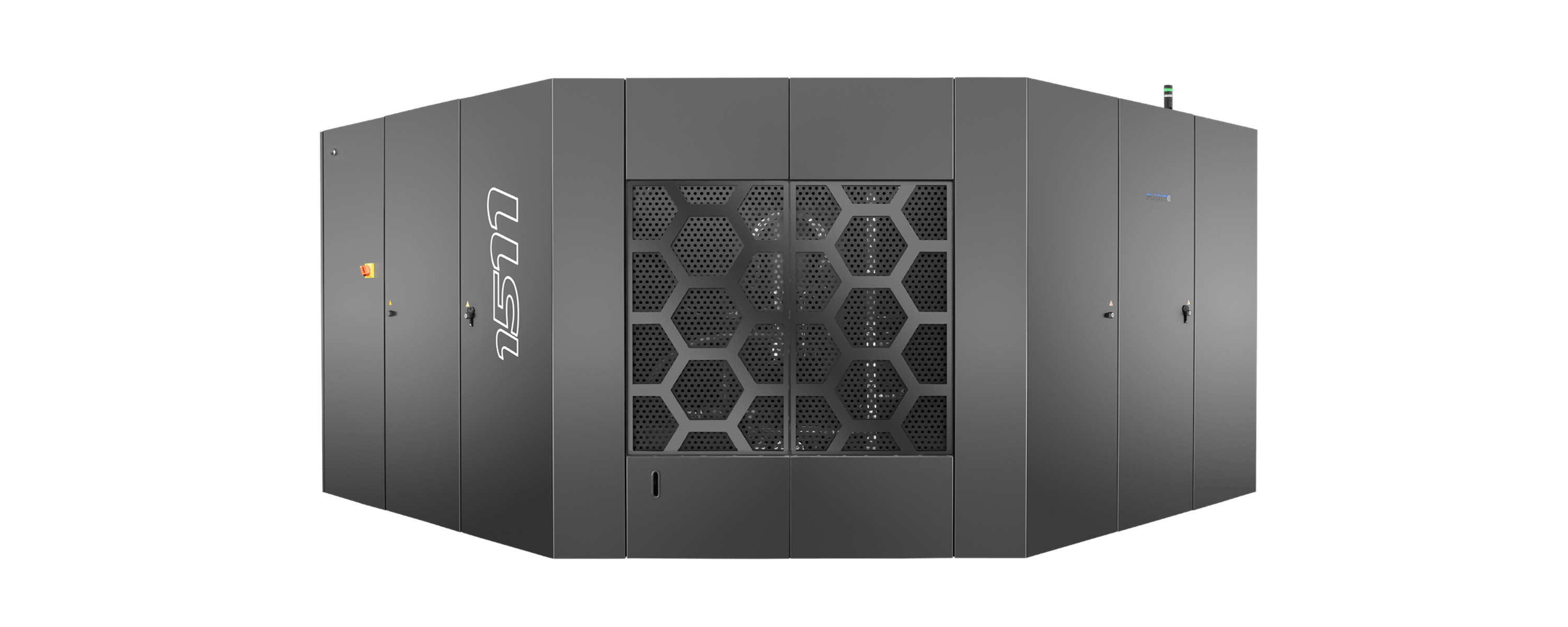

PLATIT Pi1511 – for your technological lead

The Pi1511 is a large volume PVD coating unit. It combines three rotating PLATIT LARC® XL cathodes in the door with two planar arc cathodes in the back of the chamber.

The combination of round cathodes with high performance planar cathodes allows for the deposition of selected PLATIT Signature Coatings with the usual flexibility. The LARC® XL cathodes have a very long run time and thus guarantee high productivity with low cost per coating.

Technology

- 3 LARC® XL cathodes (LAteral Rotating XL Cathode) in the door

- 2 planar cathodes in the back for arc coating

- MAC-3C (Magnetic Arc Confinement - Coil Current Compensation) for automated magnetic field adjustment

- Fast cathode change

- Deposition of selected PLATIT Signature Coatings

Etching processes

Several etching technologies can be used with the PLATIT Pi1511 coating unit, offering various advantages:

- LGD® (Lateral Glow Discharge)

- Plasma etching with argon, glow discharge

- Metal ion etching (Ti, Cr)

Load and cycle times

- Coating volume: max. ø715 x H805mm

- Coating height with defined coating thickness: max. 711mm

- Load: max. 750kg, higher weight upon request

- Batches/day: 3

Modular carousel systems

- 1-12 axes

Software

- PLATIT SmartSoftware (PC and PLC system)

- Easy operation and maintenance

- Modern user interface with menu navigation on touch screen

- Real-time process visualization incl. data recording and data management

- Manual and automatic process control

- Remote diagnosis and maintenance possible

Dimensions

- Footprint: 5000 x 2200 x 2500mm (W x D x H)