PLATIT S-MPuls – for coin minting

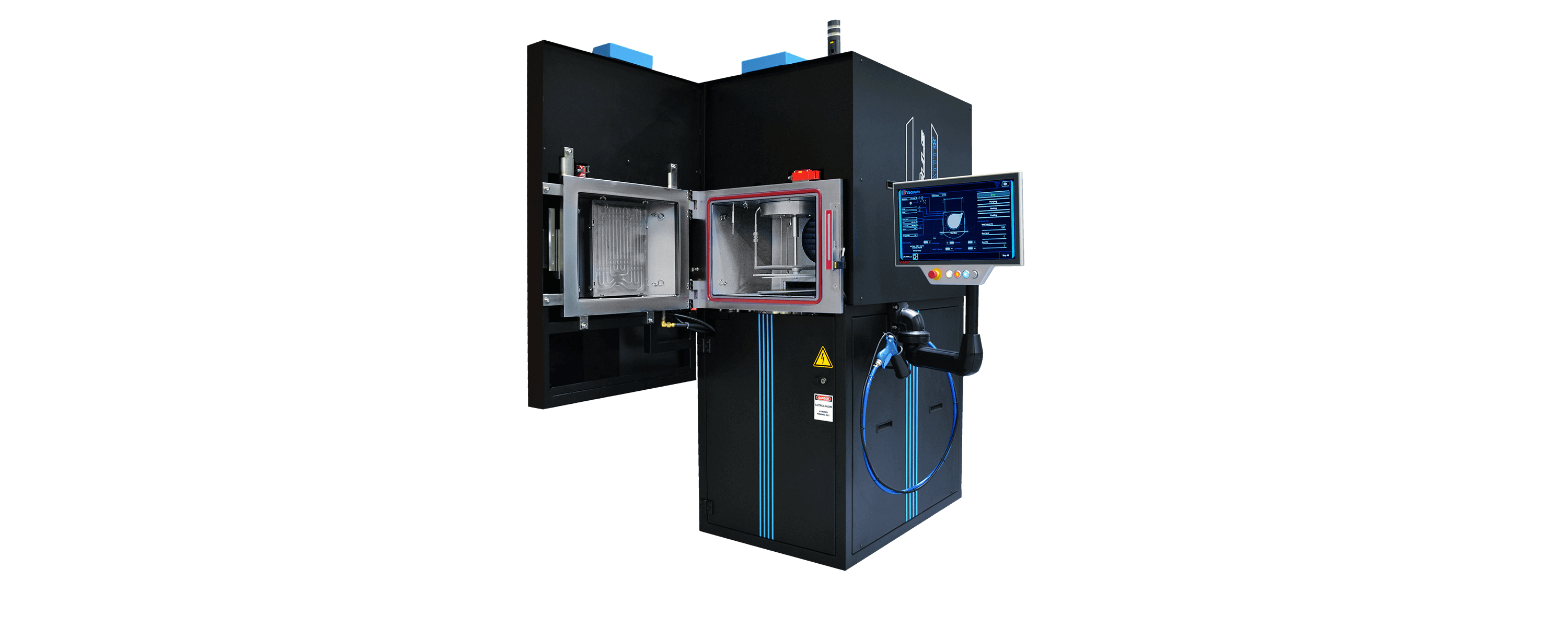

The PLATIT S-MPuls coating unit is a unit specially developed for coating polished surfaces, such as punches, stamps, dies or for coin minting.

For defect-free surfaces that meet the highest demands, effective etching is required. Therefore, we use argon etching with pulsed standard bias voltage as well as our patented LGD® (Lateral Glow Discharge) process. The surface is cleaned and activated for the adhesive layer.

By using our sputter coating technology, the coated tools reproduce the original machined surface structure without defects and deviations. The coating distribution is homogenized by a specially adapted magnetic field. The result is a high-quality coating with near-perfect imaging accuracy.

The fixtures in the S-MPuls-coating unit are tailored to the specific application. As you may need to coat different tool geometries in relation to their diameter, the holders can be adapted by additional rings. Here, it is necessary to offer a mount that prevents the tool surface from being contaminated with dust. Due to this requirement, the tools are positioned upside down facing the target, which is mounted on the bottom of the chamber. Nevertheless, changing the target is quick and easy.

The S-MPuls is the smallest coating unit in our product portfolio with a cycle time of less than 3 hours for 2 to 2.5 μm coating thickness.

Technology

- A pulsed DC magnetron sputtering cathode with rotating magnetic field

- Sputter source located at the bottom of the chamber

Etching processes

The PLATIT S-MPuls sputter coating unit has two etching processes:

- LGD® (Lateral Glow Discharge)

- Plasma etching with argon, glow discharge, with auxiliary anode

Load and cycle times

- Coating diameter with defined coating thickness: ø70-250mm

- Substrate holder: ø300mm, various customer-specific versions possible

- Load: max. 20kg

- Batches/day: 4-6, batch time 3-4.5 hours

Software

- PLATIT SmartSoftware (PC and PLC system)

- Easy operation and maintenance

- Modern user interface with menu navigation on touch screen

- Real-time process visualization incl. data recording and data management

- Manual and automatic process control

- Remote diagnosis and maintenance possible

Dimensions

- Footprint (unit): 945 x 1403 x 2068mm (W x D x H)

- Footprint (control cabinet) 608 x 1369 x 2068mm (W x D x H)

- Door opening: 450 x 615mm (W x H)