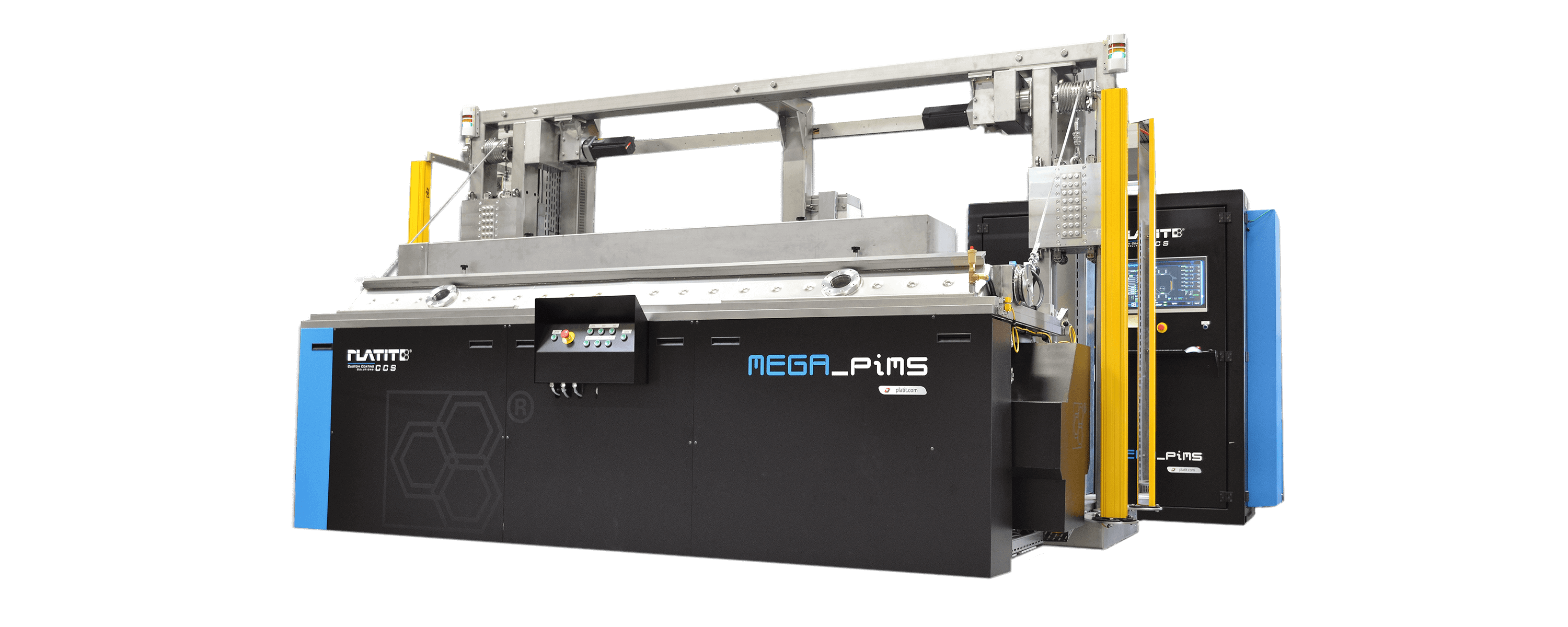

PLATIT Mega-PiMS – for rotating components

The PLATIT Mega-PiMS coating unit is specially developed for the coating of rotating components. The goal is to produce a highly polished or textured surface. To guarantee particularly smooth coatings, we use our advanced sputtering technology.

The Mega-PiMS coating unit is also specially dimensioned to meet the special requirements of rollers, which are usually too large or too heavy for our standard coating units. We developed the design and operating concept to allow you to flexibly adapt the coating unit to the weight and size of the components. The tool or component can thus be from ø100 x 450mm up to ø600 x 3000mm. The maximum uniform coating length is 2000mm with a maximum weight of up to 1000kg.

The unit is easy to use and provides the highest level of user comfort. Loading has been greatly simplified and the targets can be changed easily and quickly.

To provide you with a particularly large chamber volume, the vacuum system of the Mega-PiMS has been further developed. The cathode is located at the bottom of the coating chamber. In this way, an optimum distribution of the coating thicknesses in the vacuum chamber can be achieved, while at the same time maximizing the space available for the tools to be coated. These are arranged horizontally and rotate above the target.

The tools and components to be coated are usually made of high-speed steel and are therefore very sensitive to temperature. Therefore, the Mega-PiMS coating unit is specially designed for low temperatures.

Standard spare parts ensure ease of maintenance - this allows us to guarantee you the usual high quality of service, even for customized units.

Technology

- A sputtering cathode at the bottom of the chamber

- One anode on the opposite side

Etching processes

The PLATIT Mega-PiMS coating unit uses two etching processes:

- LGD® (Lateral Glow Discharge)

- Plasma etching with argon, glow discharge

Load

- Coating volume: max. ø600 x L3000mm

- Coating volume with defined coating thickness: max. ø600 x L2000mm

- Load: max. 1000kg (higher loads on request)

Software

- PLATIT SmartSoftware (PC and PLC system)

- Easy operation and maintenance

- Modern user interface with menu navigation on touch screen

- Real-time process visualization incl. data recording and data management

- Manual and automatic process control

- Remote diagnosis and maintenance possible

Dimensions

- Footprint (unit): 4100 x 2900 x 2700mm (W x D x H)

- Footprint (control cabinet): 1900 x 1100 x 2200mm (W x D x H)